We believe in providing the highest level of service and support for our customers. That’s why we have established a network of Enbio Authorized Service Providers - trusted professionals trained to offer both warranty and post-warranty repairs on Enbio autoclaves.

Reliable Service Near You

Enbio Authorized Service Providers

Certified Expertise

All of our authorized service providers are certified and trained according to Enbio’s stringent standards, ensuring that every repair and maintenance task is performed with the highest level of skill and precision.

Original Parts Only

Our service providers use only genuine Enbio parts, guaranteeing that your autoclave maintains its original quality and performance.

Adherence to Enbio Guidelines

Repairs and maintenance are conducted following Enbio’s official repair guidelines, ensuring consistency and reliability in every service.

Local Convenience

With a growing network of service providers, you can find reliable Enbio service closer to your location, minimizing downtime and getting you back to work faster.

Find Your Nearest Service Provider

Our network of Enbio Authorized Service Providers is expanding rapidly to meet the needs of our customers.

Use our interactive map to locate the nearest provider, and enjoy the convenience of professional service close to home.

Prefer Factory Service?

We've got you covered!

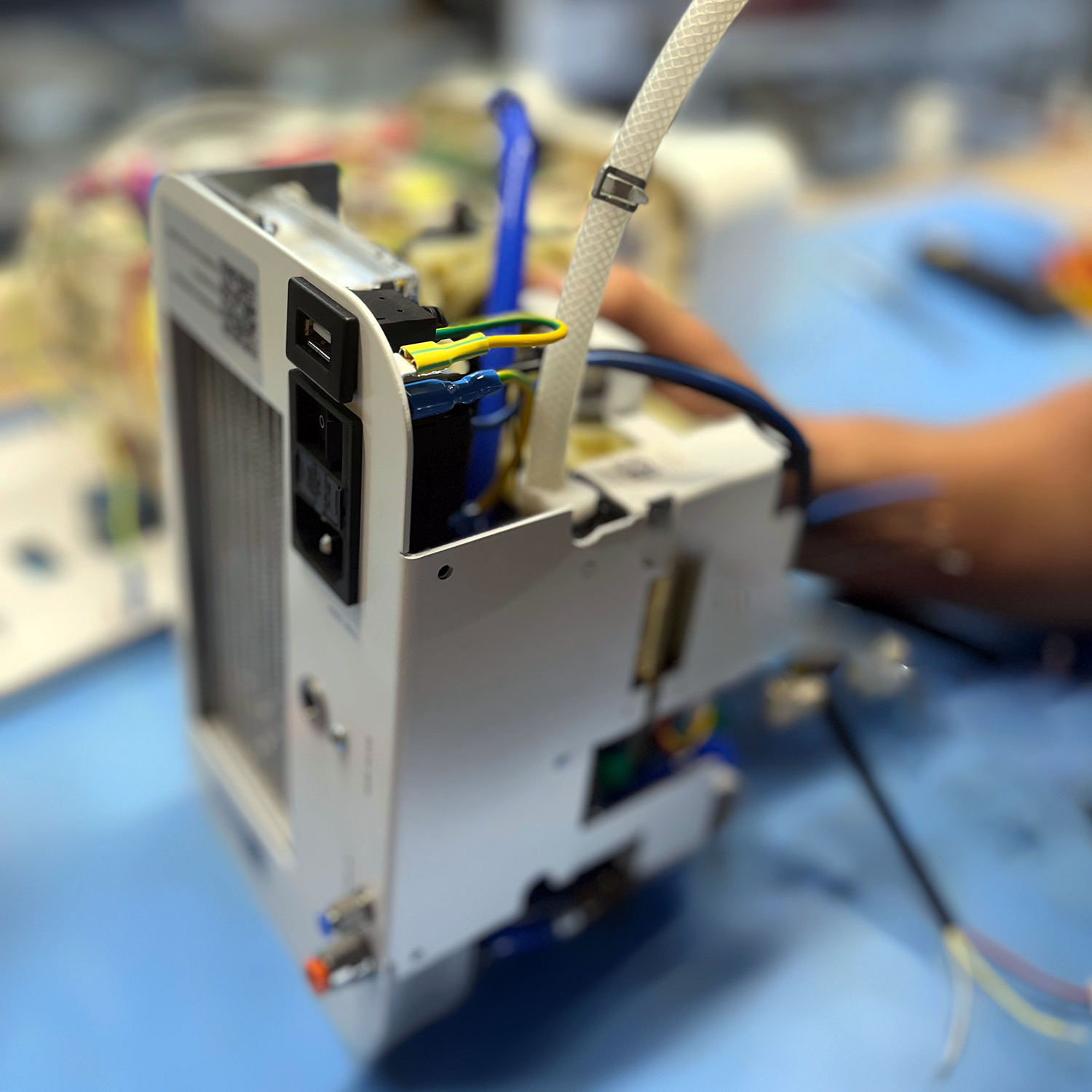

If you prefer, you can send your autoclave directly to our Factory Service for repairs.

Our factory team will ensure a thorough inspection, repair, and testing of your equipment to meet the highest standards.

FAQ

Whatservices do Enbio Authorized Service Providers offer?

Enbio Authorized Service Providers offer a range of services including periodic maintenance checks, minor and major repairs, and replacement of parts using genuine Enbio components.

What is included in the periodic maintenance check?

Periodic maintenance includes a comprehensive set of checks and replacements:

1. Performance check

* Performance check of steam generator (replacement of heaters if applicable)

* Vacuum pump performance (replacement of membranes and valves if applicable)

* Checking the error list and checking the correct performance of the sterilization process

2. Key parts replacement

* drawer gasket (after 1000 processes)

* WATER IN connector

* instrument tray

3. Maintenance

* heat exchanger cleaning (inside and outside)

* steam generator descaling

* process chamber cleaning

* drawer guides lubrication

4. Sterilization Process Validation

How often should periodic maintenance be performed on my autoclave?

Periodic maintenance should be performed annually or after 1,500 sterilization processes, whichever comes sooner. Regular maintenance ensures optimal performance and longevity of your autoclave.

How do I schedule a service with an Authorized Service Provider?

To schedule a service, please contact the Authorized Service Provider directly using the contact details provided on our website or reach out to our customer service team for assistance.